RESPIRATORY SAFETY WHEN APPLYING TELONE™

Prepping the soil with TELONE™ before planting creates a zone of protection with less nematode pressure, leading to improved crop quality and increased yields. TELONE™ contains the active ingredient 1,3-dichloropropene—a chemical that can pose respiratory hazards if not handled properly. Therefore, applicators must adhere to strict stewardship practices while handling and applying TELONE™, including wearing the correct personal protection equipment (PPE). One of the most important PPE for TELONE™ applicators is an approved respirator.

This blog post will cover how proper respirator usage can enhance safety and productivity. For more detailed information, refer to OSHA’s respiratory protection standard (29 CFR 1910.134). For your convenience, this information is also available as a downloadable PDF Tip Sheet.

FOLLOW THESE STEPS BEFORE DONNING A RESPIRATOR FOR THE FIRST TIME:

- Conduct a medical evaluation

- Before using a respirator, workers must undergo a medical evaluation to ensure they are physically capable of wearing one. This includes a medical questionnaire and possibly a follow-up exam. There are online resources available or consult your healthcare provider for more information., workers must undergo a medical evaluation to ensure they are physically capable of wearing one. This includes a medical questionnaire and possibly a follow-up exam. There are online resources available or consult your healthcare provider for more information.

- Choose the right respirator

- Pick a respirator approved by the National Institute for Occupational Safety and Health (NIOSH) for use with 1,3-dichloropropene. Typically, a NIOSH-approved organic vapor respirator with a chemical cartridge is recommended (MSHA/NIOSH approval number prefix TC-23C). Determine whether you need a half-face or full-face respirator. If you are using TELONE™ in conjunction with Chloropicrin a full-face respirator is required. A full-face respirator may also be used as an alternative to additional eye protection.

- Perform a fit test

- Fit testing is a crucial procedure to ensure that a respirator forms a proper seal on the user’s face, providing the necessary protection against substances like TELONE™. Men must be free from facial hair to achieve a proper seal.

- Qualitative Fit Testing: a pass/fail method that relies on the user’s sensory response to detect leaks.

- Quantitative Fit Testing: uses instruments to measure the actual amount of leakage into the respirator.

- Fit testing is a crucial procedure to ensure that a respirator forms a proper seal on the user’s face, providing the necessary protection against substances like TELONE™. Men must be free from facial hair to achieve a proper seal.

- Hold respirator training

- Training is a critical component of a respiratory protection program, ensuring workers are knowledgeable and equipped to handle TELONE™ safely. Training is required prior to initial use and retraining is required annually, or if new respirators are used, or if the employee indicates a need. Training should cover topics such as respirator selection and use, understanding respiratory hazards, fit testing, maintenance/care, emergency procedures, and documentation.

- Establish recordkeeping best practices

- Accurate and thorough records help track the efficacy of the respiratory protection program, verify training and fit testing, and ensure medical fitness for respirator use. It is an essential component for compliance with OHSA’s respiratory protection requirement. Records should include medical evaluations, fit tests, training, respirator issuance and maintenance, and program audits.

MAINTENANCE AND CARE

Proper maintenance and care of respirators are critical to ensuring their effectiveness in protecting workers from respiratory hazards. It is important to familiarize yourself with manufacturer recommendations for inspecting, cleaning, and storing your respirator. Cartridges should be replaced within the manufacturer-recommended interval or whenever the cartridge becomes saturated and the odor becomes evident when wearing the respirator.

WHEN SHOULD YOU WEAR A RESPIRATOR

Carefully follow all product label instructions when handling and applying TELONE™. Also be aware that federal, state, and local regulations—as well as occupational health guidelines—may require additional precautions when using respirators during the handling of TELONE™. The following list outlines various scenarios requiring the use of a respirator:

- During any handling activity that could result in liquid contact. Examples include: Unloading, loading, or transferring TELONE™ from one vessel to another. Equipment calibration. Equipment clean-up and repair. Product sampling. Small spills. Any activity less than 6 feet from an unshielded pressurized hose.

- During Application: California handlers inside the application block during application must wear respiratory protection throughout the application. Non-California handlers inside the application block must wear a respirator UNLESS they are within an enclosed cab with a vapor-adsorptive filter containing a minimum of 1000 grams of activated charcoal. This filter must be changed after no more than 50 hours of application time.

- During the Re-Entry Restricted Interval: Activities inside the treated area 1 to 5 days after application.

- Emergency Incidents: Respirators shall be worn to stop unintended product flow or to remove injured persons from areas where product inhalation may occur. Please note: high concentrations of TELONE™ may require the use of a Self-Contained Breathing Apparatus (SCBA).

AN EXAMPLE OF A HALF-FACE AND FULL-FACE RESPIRATOR

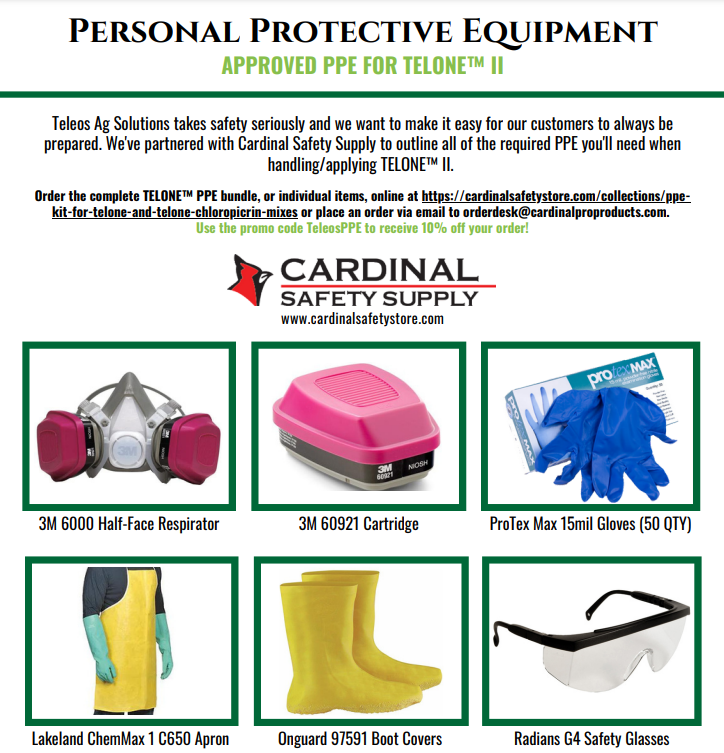

There are many brands that produce the proper half-face respirators (for straight TELONE™ applications) and full-face respirators (for TELONE™ + chloropicrin dual applications). Below are images of approved respirators by 3M. These respirators, as well as other approved TELON™E PPE, are available for purchase on the Cardinal Safety Store website. Use the code “TeleosPPE” for a 10% discount on your order!

For an overview of other TELONE™ PPE, check out this downloadable PDF overview.

Disclaimer:

The resources and information provided are meant purely for educational discussion, contains only general information about legal matters, and is not to be construed as advice. Please note that any information or resources provided are not legal or regulatory advice, and should not be treated as such. You must not rely on the information provided as an alternative to legal advice from your attorney or other professional services. Teleos Ag encourages readers to consult with counsel, and their local, county, and state regulators. We make no representations or warranties, express or implied, in relation to the information provided through our resources and blog posts. It is the readers responsibility to know the laws related to 1,3- D, appropriate PPE, Licensing, etc., in his or her City, County, State, and Country.

- EQUIPMENT COMPATIBILITY: METAL SELECTION FOR TELONE™ by TELEOS SOIL FUMIGANT - December 16, 2025

- STORAGE SECURITY FOR TELONE™ by TELEOS - October 16, 2025

- TIP SHEET: PLACARDING FOR BULK SHIPMENT RETURNS - August 15, 2025